-

- About Us

- Cooperation

- News

- Offer

- E-shop

- Contact

- TRACK FINDER

- WYSZUKIWARKA SZYB

- Kategorie produktowe

-

ALL CATEGORIES

ALL CATEGORIES

-

-

-

-

-

-

SLEW SYSTEM

-

-

-

-

-

AXLES

- TIE RODS

- KIT SPIDER FOR DRIVE SHAFTS

- DIFFERENTIAL

- MOUNT THE KNUCKLE

- HUB / GEAR REDUCTION

- PROPSHAFTS

- SOLENOID VALVES / COILS

- FLANGES / COUPLING YOKES

- BEARINGS

- BUSHES / WASHERS MOUNT AXLE

- AXLE / DIFFERENTIAL HOUSING

- DRIVESHAFTS / CENTER JOINTS

- BOLTS / NUTS / STRAPS

- LOCK / CIRCLIP / CLIP

- CROWN WHEEL AND PINIONS

- SEALS

- OTHERS

-

-

-

-

WHEELS

-

-

-

-

-

-

ENGINE

-

-

-

-

-

COILS / SOLENOID VALVES

-

SWIVELS / TURNING JOINTS

-

PUMPS / STEERING VALVES / MOTORS

-

-

-

VALVES

-

HYDRAULIC HOSES / PIPES

-

RAMS

-

ACCUMULATORS

-

QUICKHITCHES

-

-

-

BOLTS / NUTS / WASHERS

-

PUMP DRIVESHAFTS

-

SEALS VALVES / PUMPS

-

OTHERS

-

-

-

-

-

-

-

TIMING

-

EQUIPMENT

-

-

LUBRICATION SYSTEM

-

-

INDUCTION / EXHAUST SYSTEM

-

SEALS / GASKET SETS

-

ENGINE MOUNTING

-

SERVICE TOOLS

-

-

-

-

-

-

STABILIZERS

-

-

-

-

-

-

FUSES / FUSE BOXES

-

RELAYS / FLASHERS

-

REVERSE ALARM

-

-

HEATERS / BLOWERS

-

BATTERY ISOLATER SWITCH

-

-

-

-

-

OILS

-

FLUIDS

-

-

-

PAINTS

-

-

-

-

-

-

-

GLASS / CAB GLAZING

-

-

-

RUBBER SEALS - GLASS

-

ASSEMBLY KITS / ADHESIVES

-

-

-

-

-

ADAPTERS

-

BOLTS / LOCKS

-

-

-

-

HYDRAULIC INSTALLATIONS

-

TOEPLATES

-

TOOTH RIPPER

-

-

-

HYDRAULIC HAMMERS / TOOLS

-

PLOWS

-

QUICKHITCHES

-

FORKS

-

-

-

EARTH DRILL / AUGER

-

SWEEPER / COMPONENTS

-

SWINGOTILT / PLATFORMS

-

-

-

-

-

ACCESSORIES

-

DECAL / STICKERS

-

-

-

GADGETS

-

CLOTHES

-

FAN ZONE

-

-

-

- SPARE PARTS SUITABLE FOR

- JCB

- CAT

- VOLVO

- KOMATSU

- CASE

- NEW HOLLAND

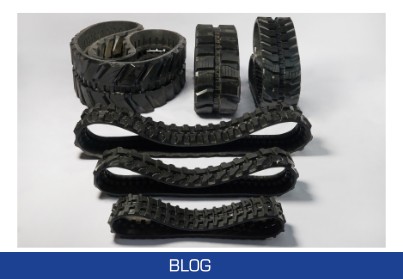

How to choose rubber tracks for excavators and mini excavators - JCB, CAT, Volvo

An essential foundation of our offer is a wide and diverse range of rubber tracks, suitable for excavators and mini-excavators from brands such as JCB, CAT, Case, New Holland, Komatsu, Volvo as well as other construction machines available on the market.

Rubber tracks are one of the most critical components in the construction of construction and agricultural machinery, responsible for their mobility and performance in challenging terrain conditions. Their quality and reliability directly affect the machine's operational efficiency and longevity. These characteristics stem from precise manufacturing and the use of the highest quality materials. The tracks we offer are made from high-grade natural rubber with a high caoutchouc content, ensuring exceptional resistance to abrasion, high temperatures, and chemical exposure. As a result, the rubber tracks are highly durable and resistant to mechanical damage, which is crucial for working in demanding conditions. Additionally, the reinforcement with stainless steel cables improves their resistance to wear and external factors. Notably, the rubber tracks are manufactured using seamless technology. This means that traditional joints, which can be vulnerable to damage in conventional tracks, are not used during the production process. The seamless construction minimizes the risk of failure, ensuring even greater reliability during operation.

The Role of Rubber Tracks in Construction Machinery

Rubber tracks play a crucial role in ensuring the mobility of machines in challenging and often unstable terrain conditions. Their primary function is not only to provide adequate traction but also to distribute the machine’s weight over a larger surface area, preventing it from sinking into the ground. This enables machines to move effectively across boggy or uneven terrain, which is essential for many construction and agricultural applications.

In addition to their stabilizing and load-bearing functions, rubber tracks also serve as shock absorbers, reducing vibrations and impacts transmitted to the machine’s undercarriage. This improves operator comfort and decreases the risk of damage to other machine components, including hydraulic systems and engines.

Maintenance of Rubber Tracks – How to Ensure Their Durability?

To ensure the long lifespan and reliability of rubber tracks, proper use and maintenance are essential. It is crucial to avoid driving over sharp edges, rocky surfaces, and high-temperature pavements, as these can damage the tread, steel cores, and weaken the rubber structure. Sharp turns, sudden reversing, or driving on a single track cause excessive material wear and increase the risk of cracks. Another important factor is maintaining the correct track tension – it should be checked every 15–20 hours of operation, and even more frequently for new tracks, to prevent slippage or over-tightening, which can lead to damage. Additionally, rubber tracks should be protected from contact with petroleum-based substances, salt, and seawater, as these can accelerate their degradation. After completing work, it is advisable to thoroughly clean the tracks of mud, stones, and other debris to prevent premature wear. Following these guidelines will not only extend the life of the rubber tracks but also ensure smooth and safe machine operation.

Rubber Track Replacement – When Is It Necessary?

Regular replacement of rubber tracks in mini excavators and excavators is crucial for their proper operation. Worn-out tracks can pose a significant risk to work efficiency. Operating on tracks that have lost their traction and shock-absorbing properties leads to increased fuel consumption, reduced machine stability, and a loss of precision in performing tasks. Furthermore, continuous stress on uneven terrain can cause the undercarriage system to overheat, accelerating the wear of other components such as bearings, drives, and suspensions. In more severe cases, this can lead to serious mechanical failures, resulting in costly repairs and work downtime.

Selecting the Right Rubber Tracks

Choosing the right rubber tracks for your machine is just as important as their proper maintenance. Each track is marked with key parameters such as width, pitch, and the number of links (e.g., 300x52.5x80). To avoid issues with tension and undercarriage wear, it is essential to select a model that meets the machine manufacturer's specifications. Incorrectly fitted rubber tracks can cause excessive wear on the undercarriage components, shortening their lifespan and increasing the risk of machine damage. It is also crucial to consider the quality of materials— tracks made from high-grade rubber and reinforced with a steel core are more resistant to heavy use. Before purchasing, it is advisable to check whether the tracks are compatible with the drive wheels and guide rollers, ensuring smooth power transmission and stable movement.

Properly fitted tracks guarantee efficient, safe, and trouble-free machine operation in all types of terrain. To streamline the selection process, it is helpful to prepare information about your machine model and the required track dimensions in advance. This allows our sales team to quickly identify the right part. If standard matching is not possible, our specialists will do their best to find the appropriate track based on the machine's VIN number.

We offer a wide range of rubber tracks compatible with nearly every type of construction equipment—most available for immediate delivery. Feel free to explore our product range and contact us at +48 172303300 or via email at biuro@serwis-kop.pl.

Related posts

The coronavirus pandemic

The coronavirus pandemic

Machine maintenance

Machine maintenance

We are present on the market for 14 years.

We are present on the market for 14 years.

Do you have trouble finding and selecting parts for your machine? The price is too high and the quality is questionable?

Do you have trouble finding and selecting parts for your machine? The price is too high and the quality is questionable?

About JCB brand

About JCB brand

WE OFFER PRODUCTS OF THE BEST BRANDS

ul. Podkarpacka 57A, 35-082 Rzeszów

NIP: 813-352-97-49 REGON: 180286726

Opening hours

Telephone support - Monday - Friday (8:00 AM – 5:00 PM)

Order pick-up - Monday - Friday (8:00 AM – 4:30 PM)

biuro@serwis-kop.pl

daniel@serwis-kop.pl

Gadu-Gadu communicator

GG: 4185846 - Daniel

+48 17 864 31 00

+48 17 864 00 24

+48 17 864 25 96

Mobile phone

+48 607-700-547

+48 695-944-818

+48 691-330-531

+48 690-906-751

Fax

+48 17 864 31 20